Case Studies

Providing precision die stamping services to customers across North America, ART Metals Group is a leader in progressive die stamping, tooling, and manufacturing. We specialize in providing quality products produced on time and under budget. Here are some examples of the value added services that we provide our customers every day.

Stainless Steel Clip for the Material Handling Industry

The ability to blank and form whether in a progressive die or in multiple operations based on your part details and volume.

Copper Cup for the Military Industry

This part was machined from large ingots of copper at a high cost until we introduced our lower cost stamping solution.

Coined Serrated Washer for the Automotive Industry

The ability to move metal is an ART. Our team understands how to meet your unique part needs even with complex geometries using our side-knuckle coin presses. Let us show you what we can do.

Progressive Die Stamping of Fiber Optic Connectors for the Electrical Industry

ART is able to combine multiple steps in the same die to create a finished part using progressive dies. What can we do for you?

Steel Roller Bearing Assembly Components for the Automotive Industry

Tight tolerance held to .001” is possible with the expertise at ART. Challenge us with your application.

Progressive Stamping of an Aluminum Damper Cover for the Aviation Industry

Once volumes reach a certain amount, conventional machining and fabricating is no longer cost effective. ART can help you convert to hard tooling and reduce your part price!

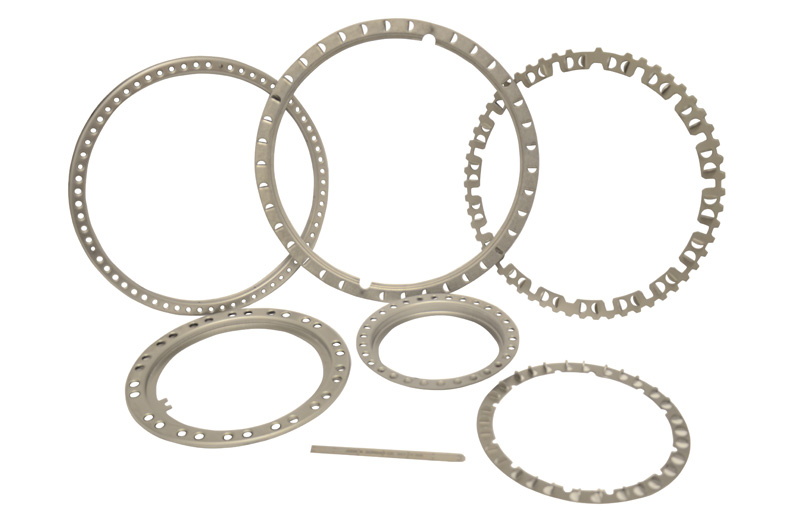

Progressive Die Stamping of Transmission Components for the Automotive Industry

Close tolerance, progressive die stamping is a core competence at ART. Let us see how our team can support your needs.

Automatic Thrust Bearing Assembly Machine

Assembling bearings to meet requirements in various industries such as automotive, heavy truck, industrial and rail requires consistently holding tight tolerances and the highest quality. ART holds IATF-16949 and ISO-9000 certifications to help drive our quality systems.

Custom Inspection Systems for Automotive Parts Production

Getting the highest quality parts is imperative in today’s world. ART uses high speed cameras to ensure our parts meet your requirements 100% of the time for our washers. Cameras are also used on our semi-automated and fully automated bearing machines.